Mechanical Ventilation with Heat Recovery (MVHR) is becoming a standard feature in high-performance homes. By supplying filtered fresh air and extracting stale air while recovering up to 90% of the heat energy, it creates healthier indoor environments and reduces energy bills.

But the benefits only come if MVHR is properly integrated from the design phase. Retrofitting ductwork, plant space, or airtightness details at the end of a project can be messy, expensive, and compromise performance.

This guide breaks down what architects, builders, and homeowners should consider at the design stage when planning for a centralised MVHR system.

Why Early Planning Matters

Efficiency: Poorly thought-out duct routes increase resistance and energy use.

Comfort: Incorrect grille placement can lead to draughts, noise, or uneven airflow.

Cost: Adding bulkheads or altering layouts late in the build inflates costs.

Compliance: Passive House or airtightness targets require coordination from the beginning.

In short: plan MVHR early, and you’ll get a system that disappears seamlessly into the home while working exactly as intended.

Key Design Phase Requirements

1. Plant Space for the Unit

- Allocate a dedicated location such as a Laundry room or hallway cupboard for the MVHR unit.

Ensure the unit is accessible for filter changes (usually every 6–12 months).

Think about acoustics: Even though the units are quiet it is best to avoid having them installed in bedrooms.

Allow clearance around the unit for servicing. Different units will require different space for installation.

Allow Access: The unit will need access for filter changes and any servicing.

2. Ductwork Planning

Centralised MVHR requires a network of supply and extract ducts. Getting this right early makes all the difference.

Duct routing: plan main distribution runs in ceiling voids, dropped bulkheads, or service cavities so that they are installed within the thermal envelope of the build.

Avoid sharp bends: every 90° bend adds pressure loss and reduces system efficiency. We use a semi rigid duct that allows for reasonable tight bends without using sharp 90 deg bends.

Separate from other services: coordinate with electrical and plumbing layouts making sure the ducts don’t cross where things like light cutouts will be in the ceilings.

Insulation: ducts passing through unconditioned spaces (roofs etc) must be insulated to prevent the effects of heat and coolth in the space. These can either be sleeved in an insulated flex duct of cover with insulation to box them in.

3. Fresh Air Intake and Exhaust Placement

If using seperate grilles, plan for at least 1.5–2 metres separation to avoid recirculating exhaust air.

Place intakes away from sources of pollution such as driveways, chimneys, and flues.

Consider prevailing wind and sun exposure when deciding orientation.

While exhaust air can go out through the roof it is not advisable to take fresh air from the roof.

If using a combined grille (as pictured) make sure the minimum spacing for airflow clearance is allowed for.

4. Room-by-Room Ventilation Strategy

MVHR works best when supply and extract points are carefully distributed:

Supply air: living rooms, bedrooms, studies — the “dry” areas.

Extract air: kitchens, bathrooms, laundries, toilets — the “wet” areas.

Transfer: air naturally flows under doors and through hallways from supply to extract zones.

Balancing: supply and extract volumes must match to avoid pressurising or depressurising the home.

Early design work should include airflow calculations, ensuring each room gets the correct volume based on occupancy and use.

5. Airtightness and Building Envelope

The success of MVHR relies heavily on airtightness.

Target: Whilst the lower the ACH (air changes per hour) the more efficient the MVHR system will be, they will work in any house. If the house is leaky the unit will still provide fresh filtered air but the heat recovery effect will be reduced.

Detailing: plan for airtight service penetrations using tapes, membranes, and grommets.

Testing: schedule blower door tests during construction to identify and fix leaks before finishes go on.

Envelope coordination: ensure duct penetrations through the airtight layer are sealed.

6. Integration with Other Building Services

MVHR does not replace heating and cooling— it can help to balance and smooth the background temperature.

Heating/cooling loads: high-performance homes often require smaller air conditioning systems.

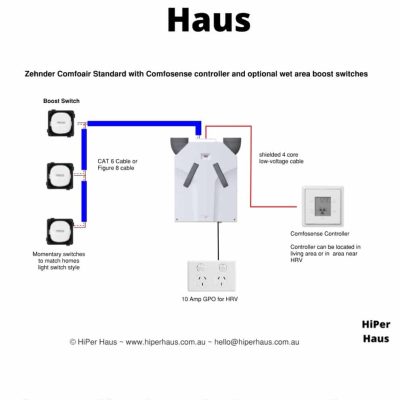

Controls: consider boost switches (kitchen/bathroom), humidity.

Smart Home integration: Some systems allow for external CO₂ sensors, and integration with smart home systems.

Exhaust overlap: MVHR can often replace exhaust fans in wet areas.

7. Maintenance and Homeowner Usability

A well-designed system is one the homeowner can actually maintain.

Filter access: filters should be quick and easy to swap without tools.

Cleaning: provide access hatches to key ductwork for occasional cleaning.

Education: plan for homeowner handover, including filter schedules and basic troubleshooting.

Longevity: choose a location that will remain accessible for the lifetime of the system.

Design Check-List for Centralised MVHR

Here’s a quick summary of what needs to be locked in during design:

✅ Dedicated plant space with service access

✅ Planned duct routes with minimal bends and conflicts

✅ Separated and well-positioned intake and exhaust grilles

✅ Room-by-room ventilation strategy with airflow calculations

✅ Airtight detailing coordinated with blower door testing

✅ Integration with controls (if applicable)

✅ Maintenance access for filters and duct cleaning

Conclusion

Centralised MVHR is not just a ventilation upgrade — it’s part of the home’s overall performance strategy. By designing with it from day one, you avoid compromises, reduce costs, and deliver a healthier, more efficient home that lives up to the promise of high-performance building.

👉 At HiPer Haus, we partner with builders, designers, and homeowners throughout the design and construction process — from concept layouts to final commissioning — to make sure MVHR systems perform exactly as they should.